Two kinds of circuit breakers commonly used in 10kV power distribution system In the electrical design of civil buildings, the following two circuit breakers are commonly used in 10kV systems. Vacuum interrupters are widely used in utility power transmission systems, power generation unit, and power-distribution systems for railways, arc furnace applications, and industrial plants.

Sulfur hexafluoride circuit breakers protect electrical power stations and distribution systems by interrupting electric currents, when tripped by a protective relay. Instead of oil, air, or a vacuum, a sulfur hexafluoride circuit breaker uses sulfur hexafluoride (SF6) gas to cool and quench the arc on opening a circuit.

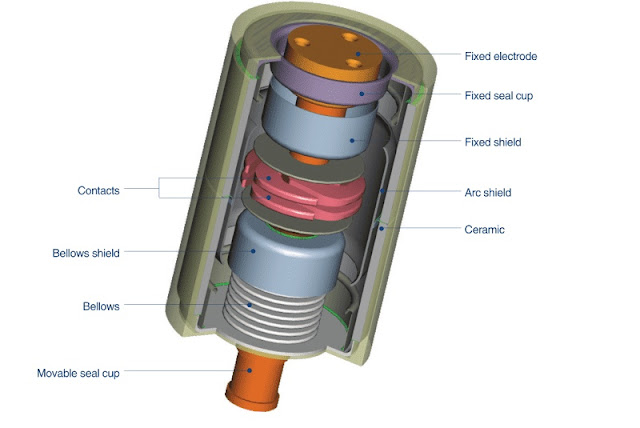

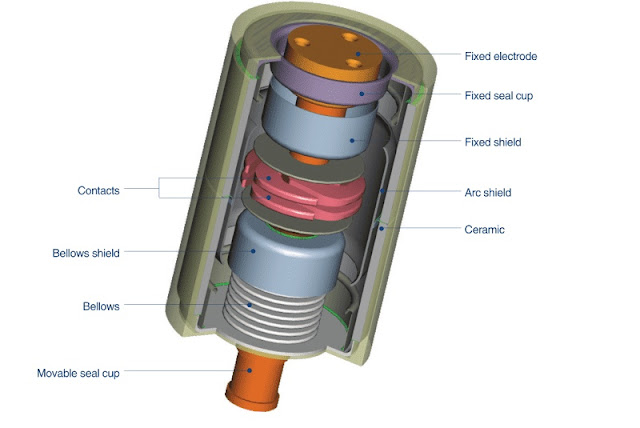

The contact of the vacuum circuit breaker, as Tavrida Electric, cuts off the circuit in the high vacuum arc extinguishing chamber, and the insulating medium and the arc extinguishing medium used are high vacuum air. There is basically no substance that can be ionized in the arc extinguishing chamber.

In any case, when the contacts are separated, the arc channel between the contacts is only composed of the metal vapor of the contact material.

The advantages of vacuum circuit breakers are small contact distance and fast action; short arcing time and fast arc extinguishing; small size, light weight, fire and explosion prevention; suitable for frequent operation.

SF6 circuit breakers use sulfur hexafluoride gas as the insulating medium and arc extinguishing medium. Sulfur hexafluoride has relatively excellent insulating ability and arc extinguishing ability. Compared with air, its insulating ability is about 2.5~3 times higher.

SF6 circuit breakers mostly use the arc extinguishing principle based on the combination of thermal expansion and compressed air assisted blowing. This technology has been widely and maturely applied in the field of high-voltage switchgear. It has smooth breaking characteristics and will not intercept current when breaking current. Therefore, no operating overvoltage is generated, and damage to the life of the capacitor bank can be avoided.

After the SF6 circuit breaker is opened, the contact burns are relatively slight, which prolongs the maintenance period and is also suitable for frequent operation.

Sulfur hexafluoride circuit breakers protect electrical power stations and distribution systems by interrupting electric currents, when tripped by a protective relay. Instead of oil, air, or a vacuum, a sulfur hexafluoride circuit breaker uses sulfur hexafluoride (SF6) gas to cool and quench the arc on opening a circuit.

Vacuum Circuit Breaker

The contact of the vacuum circuit breaker, as Tavrida Electric, cuts off the circuit in the high vacuum arc extinguishing chamber, and the insulating medium and the arc extinguishing medium used are high vacuum air. There is basically no substance that can be ionized in the arc extinguishing chamber.

In any case, when the contacts are separated, the arc channel between the contacts is only composed of the metal vapor of the contact material.

The advantages of vacuum circuit breakers are small contact distance and fast action; short arcing time and fast arc extinguishing; small size, light weight, fire and explosion prevention; suitable for frequent operation.

SF6 Circuit Breaker

SF6 circuit breakers use sulfur hexafluoride gas as the insulating medium and arc extinguishing medium. Sulfur hexafluoride has relatively excellent insulating ability and arc extinguishing ability. Compared with air, its insulating ability is about 2.5~3 times higher.

SF6 circuit breakers mostly use the arc extinguishing principle based on the combination of thermal expansion and compressed air assisted blowing. This technology has been widely and maturely applied in the field of high-voltage switchgear. It has smooth breaking characteristics and will not intercept current when breaking current. Therefore, no operating overvoltage is generated, and damage to the life of the capacitor bank can be avoided.

After the SF6 circuit breaker is opened, the contact burns are relatively slight, which prolongs the maintenance period and is also suitable for frequent operation.

Comments

Post a Comment